Lime Guidelines for Field Crops in New York

Amy Barkley, Livestock Specialist

Southwest New York Dairy, Livestock and Field Crops Program

Lime Guidelines for Field Crops in New York, written by Quirine M. Ketterings, W. Shaw Reid, and Karl Czymmek

Selections from the full article have been used in this write-up.

INTRODUCTION

Achieving optimum pH is essential for field crop production because soil pH affects many soil properties and processes including nutrient cycling, soil microbial activity and soil structure. The native pH of a soil is determined by the type(s) of rock, or parent material, the soil was developed from. The characteristics of the parent material influence soil mineralogy and the quantity of exchangeable cations that determine soil pH. Most agricultural soils in New York are acidic and have a pH ranging from 4.5-7.0. Some New York soils are "calcareous", meaning they contain free calcium carbonate, or lime deposits in the surface layer. Calcareous soils tend to have a pH in the range of 7.0- 8.5 and the pH tends to be quite stable, so pH management is usually not an issue. However, naturally acidic agricultural soils need to be monitored for pH and lime will need to be applied for optimum field crop production.

SAMPLING A FIELD FOR PH

It is recommended to test each field for pH (and fertility) at least once in 3 years or twice per rotation. If the past field management is unknown, more frequent sampling is highly recommended as it will help to establish a reliable assessment of lime and fertilizer needs. Take a minimum of 10-15 subsamples from across a field (identified as an area differing from its neighboring areas in crop growth, soil type, drainage, fertility levels, and/or past management). Typically, a sampled unit should not be more than 10-15 acres unless past experience indicates wider uniformity. If considerable within-field variability in pH is expected, grid sampling is recommended as variable rate application of lime can be economically and environmentally advantageous.

Soil samples can be taken at any time during the year when the soil is not frozen or saturated. Due to seasonal variability of nutrient availability (and pH), it is recommended to sample at about the same time in the year. For conventional tillage systems, a sample core from 0-8 inches is recommended. Under minimum or no-tillage systems, the surface inch of the soil may become acid more rapidly than the deeper layer so in no-till or minimum tillage systems, the pH values of two soil layers (0-1 and 0-6 inches) should be determined.

It is recommended to test each field for pH (and fertility) at least once in 3 years or twice per rotation. More frequent sampling will result in a more reliable assessment of past field management and current lime needs.

LIMING MATERIALS:

New York State law defines agricultural liming material as: "all materials and all calcium and magnesium products in the oxide, hydrate, carbonate or silicate form or combinations thereof and intended for use in the correction of soil acidity, including such forms of material designated as burned lime, hydrated lime, carbonate of lime, agricultural limestone, slag and marl" Common materials are listed below:

CaO - Calcium Oxide (Lime, Burned Lime, Quick Lime)

Ca(OH)2 - Calcium Hydroxide (Hydrated Lime, Slaked Lime)

CaCO3 - Calcium Carbonate (Calcitic Limestone)

CaCO3, MgCO3 - Ca and Mg Carbonates (Dolomitic Limestone)

It is a fairly common misconception that gypsum is a liming material. Gypsum is calcium sulfate (CaSO4). The Ca in gypsum can displace the H+ and Al3+ on the soil's exchange complex but the sulfate cannot neutralize the acidity. Thus, gypsum is not a liming material. It is however, an excellent source of calcium and sulfur because it does not alter soil pH.

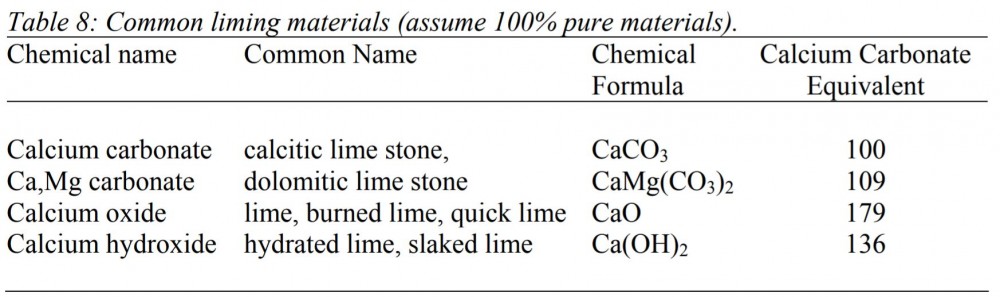

To compare one liming material with another, quality standards must be used. The total neutralizing value (TNV) of a liming material is usually expressed as the Calcium Carbonate Equivalent (CCE) of the material.

To calculate the CCE of a lime source, divide 100 by the molecular mass of the liming material and multiply this ratio by 100. For example, the molecular mass of CaO is 40+16=56 so the CCE of pure CaO is (100/56)*100=179% (Table 8). This means that 1 ton of CaO will neutralize as much as 1.79 tons of pure calcium carbonate. In other words, if one ton of pure calcium carbonate is needed, this requirement can be met with 100/179=0.56 tons of CaO.

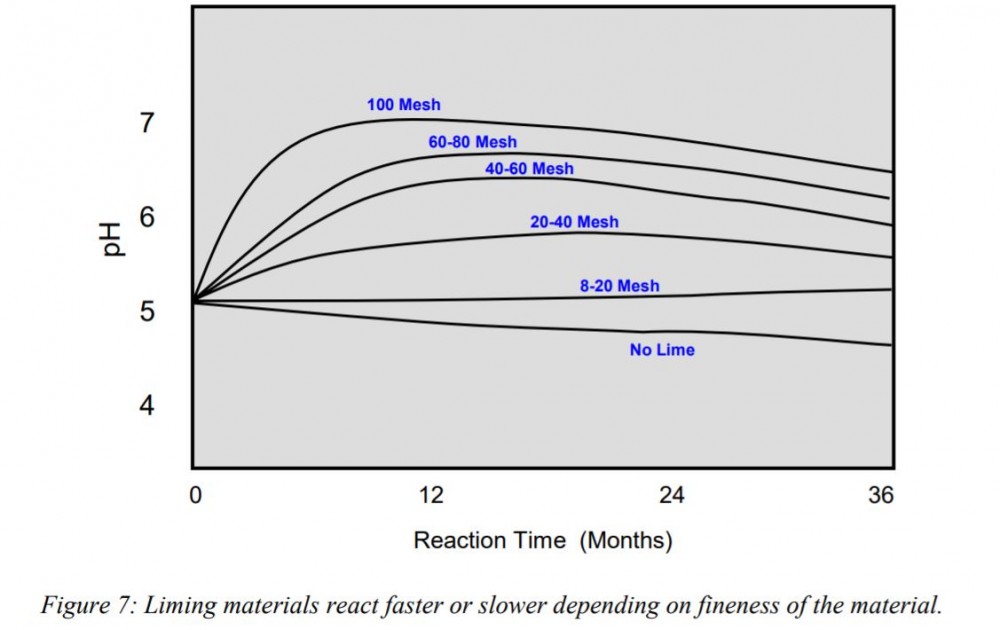

For a given amount of acidity, a corresponding amount of liming material is needed regardless of the fineness of the material. However, the finer the material, the quicker it will react (Figure 7). Particle size distribution is measured by passing the material through a set of sieves. Sieve sizes are expressed as the number of wires per inch so materials that pass through a 100 mesh sieve are much finer than materials that pass through a 60 mesh sieve. The rate of reaction of a liming material is determined by the particle sizes of the material; 100% of lime particles passing a 100-mesh screen will react within the 1st year while only 60% of the liming materials passing a 20-mesh sieve (but held on 100 mesh sieve) will react within a year. Material that does not pass the 20 mesh sieve is not expected to react within a 1 year following application. Oxides and hydroxides are typically in powder form so 100% of the material is assumed to react within the year of application. These materials react with water so care must be taken to avoid direct contact with skin and eyes. For other lime sources, CCE needs to be adjusted for the fineness of the material.

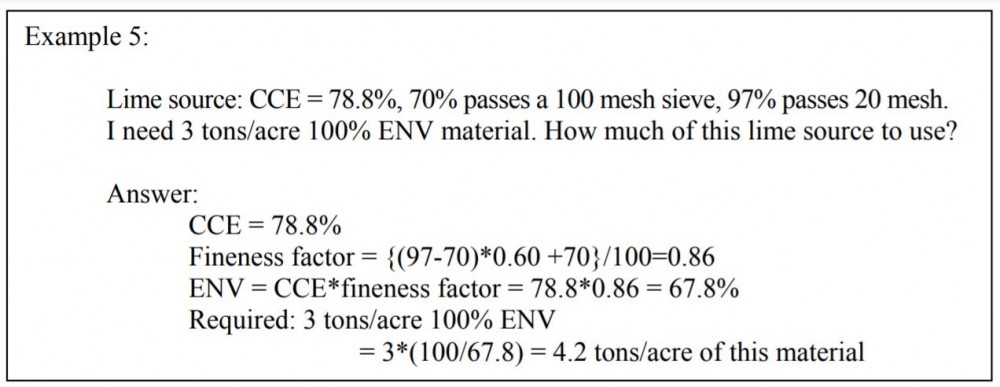

To determine the fineness factor of a limestone (1) subtract the % passing a 100 mesh sieve from the % passing a 20 mesh sieve and multiply this percentage by 0.60; and (2) add the % passing the 100 mesh sieve to the value obtained in step 1 and divide the sum by 100.

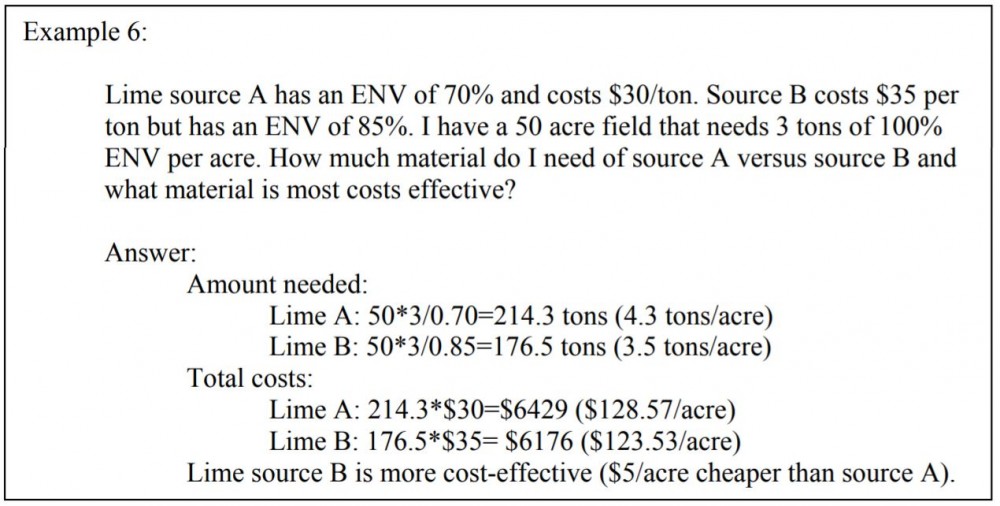

For example: the fineness of a material of which 70% passes a 100 mesh sieve and 97% passes a 20 mesh sieve is {(97-70)*0.60 +70}/100=0.86. Once we know the CCE and the fineness of a liming material, we can calculate its Effective Neutralizing Value (ENV). The ENV is calculated by multiplying a liming material's CCE and its fineness factor. As an example: a liming material with CCE of 90% and a fineness of 0.86 has an ENV of 90*0.86= 77.4. As mentioned before, recommendations on a soil test report are based on 100% ENV equivalent material. To determine the actual application rate, divide the recommended rate by the ENV and then multiply by 100. Thus, if 2 tons/acre 100% ENV is recommended, this can be satisfied with 2 tons/acre calcitic limestone, 1.1 ton/acre burned lime (2/179*100), or 1.5 tons/acre hydrated lime (2/136*100). To compare liming materials for cost effectiveness, compare the price per ENV and not the cost per lbs of product. Examples are given below.

If a soil is deficient in magnesium, the use of dolomitic limestone is recommended as it is the most economic way to provide magnesium to acidic soils.

NEW YORK LIME LAW

The New York State Department of Agriculture and Markets (NYSDAM) regulates agricultural liming materials as outlined in Article 9-A: Sale of Agricultural Liming Materials (http://public.leginfo.state.ny.us/menuf.cgi, link to "Laws of New York", AGM Agriculture and Markets, Article 9-A "Sale of Agricultural Liming Materials"). Sections 142-cc and 142-gg in Article 9-A state that for New York, a liming material must be properly labeled with guaranteed analyses and have a CCE of 60% or greater, at least 80% must pass a 20 mesh sieve, and 30% must pass a 100 mesh sieve. This implies that the fineness factor should be greater than or equal to 0.60 and that the ENV should be 36% or greater:

TIMING CONSIDERATIONS

Successful crop production, especially with pH sensitive legumes, requires pH adjustments well in advance of planting. If the soil pH is 6.0 or less and a new legume seeding is planned, the liming materials should be applied at least six months before seeding for the lime to react with the entire plow layer. If there is insufficient time for an adequate reaction, half of the recommended lime should be plowed down and the remainder disked into the soil surface before seeding. If the pH is 5.5 or lower, apply lime and defer seeding until next year (for no-till seeding guidelines see Section 5: Calculating Lime Requirements). Many New York State farmers have had great success with applying soil test based recommended lime rates for alfalfa fields while the field is still in corn. Another approach is to lime during the last year of hay in the rotation, making the lime application directly after second or third cutting when soils are dry and best able to support heavy lime application equipment, thus minimizing the risk of soil compaction. Also, as the sod re-grows, it will help prevent runoff of the lime as a result of heavy rains on fields that prone to runoff. Lime applied to corn stubble requires some type of incorporation (light disking, field cultivator, or chisel plow). A cover crop of oats or winter rye will help provide further protection against soil erosion. If a rapid increase in pH is desired, calcium oxide (burned lime or quick lime) or hydroxide sources (hydrated lime or slaked lime) can be considered. These sources increase the pH of the soil much faster than calcitic or dolomitic limestones. This could be desirable if a quick increase in pH is needed. However the effects are of shorter duration. Additional care must be taken when handling calcium oxide and hydroxide sources as they react quickly with water.

Regardless of crop, when the lime requirement is greater than 4 tons/acre, plow down half of the lime required and work the remainder into the surface. Generally, for economic returns, it is recommended to not apply more than ~6 tons 100% ENV within a 4 to 5 year rotation. If more is required, apply up to 6 tons in the current rotation and retest the soil again in 3 years. If rates are desired on a 1,000 square feet basis, rates in tons/acre need to be divided by 0.02 to equal pounds of lime per 1,000 square feet.

---

Relevant Cornell Agronomy Fact Sheets include:

Agronomy Fact Sheet # 1: Soil Sampling for Field Crops

Agronomy Fact Sheet # 5: Soil pH for Field Crops

Agronomy Fact Sheet # 6: Lime Recommendations

Agronomy Fact Sheet # 7: Liming Materials

These Fact Sheets are accessible at: http://nmsp.cals.cornell.edu/g...

The article cover photo is from Michigan State University.

Upcoming Events

WEBINAR - Automated Milking Systems Efficiency: Balancing Focus on Individual Cows and System Optimization

May 8, 2024

Please join Cornell the SWNY team and MSU Extension for our talk with Dr. Pablo Silva Boloña on improving efficiency of Automated milking systems by focusing on milking settings for individual and group success.

Broiler Field Day at Sunny Cove Farm

June 6, 2024

Alfred Station, NY

Join us for a field day to explore broiler production, processing, and finances. Meghan Snyder of Sunny Cove Farm will be our host. She raises small batches of organic broilers, processing them on-farm under the 1,000 bird exemption.

Stockmanship and Stewardship 2024

October 25, 2024

Hamburg, NY

Save the date!! The event is one of 4 across the US and is a two-day educational experience featuring low-stress cattle handling demonstrations, Beef Quality Assurance educational sessions, facility design sessions, and industry updates.

Announcements

No announcements at this time.